Discover the Versatile Uses of Membrane Switch Over in Modern Electronics

In the world of contemporary electronic devices, the application of membrane buttons is remarkably considerable, covering from streamlined consumer gizmos to important medical gadgets. As sectors continue to advance, the assimilation of membrane buttons in equipment style is crucial, promising not just to meet yet exceed the extensive needs of both functionality and visual allure.

Exploring the Function of Membrane Layer Changes in Customer Electronics

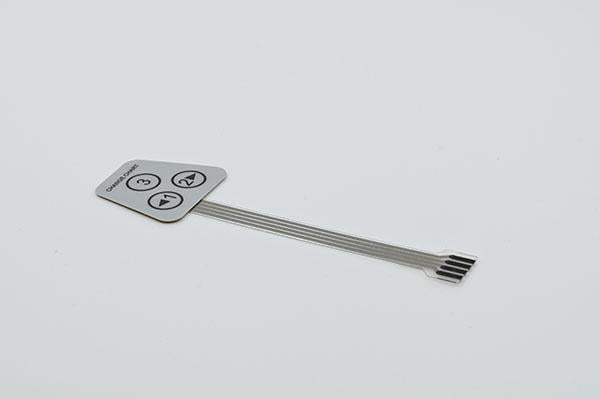

Why are membrane layer switches over so common in customer electronics? The solution depends on their special combination of cost, reliability, and flexibility. Membrane layer buttons are cost-efficient to produce, making them an eye-catching option for high-volume production regular in consumer electronics. Their building, featuring a slim, adaptable layer that can quickly be integrated right into various tools, enables smooth, portable item layouts.

Furthermore, these switches are understood for their durability and low upkeep. They are resistant to dust, dust, and dampness, which enhances the longevity of the electronic devices they are used in. This reliability is crucial in everyday customer items that undertake constant use. Furthermore, their versatility in layout enables personalization in aesthetic appeals and performance, dealing with the specific demands of various electronic devices. From microwave to push-button controls, membrane switches give a functional, easy to use interface that supports the vibrant nature of consumer electronic devices.

Membrane Layer Changes in Medical Devices: Enhancing Customer Interfaces

Membrane buttons additionally play a significant role in the world of clinical tools, where they boost user interfaces with their unique advantages. The smooth, closed surface area of membrane layer switches over permits for very easy disinfection, lessening the threat of contamination and spread of virus.

Membrane layer buttons additionally add to the resilience of medical tools. Their resistance to fluids and impurities makes sure that vital equipment continues to be operational in various clinical settings, consisting of surgical procedures where direct exposure to liquids is typical. This longevity, paired with tactile feedback and low-profile layout, makes membrane changes an essential component in improving the performance and security of medical tool user interfaces.

The Impact of Membrane Layer Turns On Industrial Tools Layout

In the realm of commercial important source devices layout, the consolidation of membrane layer buttons has actually noted a significant evolution. The slim profile of membrane switches allows for more compact device layouts, while their resistance to dirt, chemical, and water impurities makes them suitable for commercial setups.

Additionally, the customizability of membrane switches enables developers to integrate specific responsive feedback and graphical overlays that boost the individual experience and boost efficiency. This assimilation sustains drivers in accomplishing precision control over complicated machinery. The general impact is a significant enhancement in the capability, integrity, and user-friendliness of commercial devices, aligning with the enhancing demands for technological development and operational performance in contemporary markets.

Conclusion

Membrane buttons have changed contemporary electronic devices, providing streamlined, resilient, pop over here and adjustable interfaces across numerous sectors. This modern technology not only satisfies the requiring problems of various fields however additionally considerably enhances customer experience, making membrane changes a foundation of modern electronic layout.

In the realm of modern electronic devices, the application of membrane layer buttons is remarkably substantial, extending from streamlined consumer gadgets to important medical gadgets.Why are membrane layer switches over so prevalent Going Here in consumer electronics? Membrane buttons are cost-efficient to manufacture, making them an attractive choice for high-volume production normal in customer electronic devices. From microwave stoves to remote controls, membrane layer buttons give a practical, user-friendly interface that supports the dynamic nature of consumer electronic devices.